Development of bio-filament using hemp fiber for 3D-printer

DOI:

https://doi.org/10.60136/bas.v10.2021.156Keywords:

Biocomposite, Hemp, 3D-printerAbstract

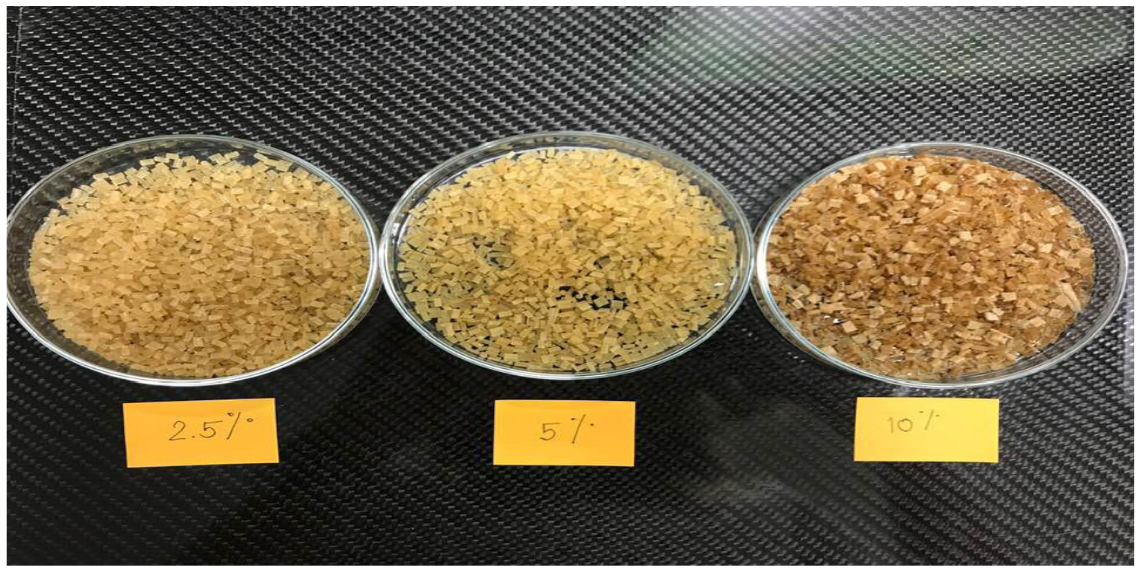

This work is a preliminary study about the use of hemp fiber as filler in a biopolymer, i.e. polylactic acid (PLA), and the following use of such composites in the 3D printing via FDM technique. In particular, hemp fiber (average length 150 micron) was added via melt-compounding into PLA 2003D at different weight percentages (1, 2.5, 5 and 10%wt). We observed that not only tensile strength increased with the increased of hemp fiber content, but also increase in brittleness. Moreover, PLA/1%wt hemp fiber was chosen to study the optimal amount of plasticizer. To solve the brittleness problem, we adjust the flexibility of the material by adding the plasticizer Polyethylene glycol (PEG) ratio 2.5 and 5%wt, respectively. The results showed a remarkable increase in the elongation at break of material, which is a necessary feature to form a 3D printed filament for 3D printing.

References

Calin C.E. (2020). Where hemp meets the road : Automotive bioplastics. [online]. [viewed 19 January 2021]. Available from: https://newfrontierdata.com/cannabis-insights/where-hempmeets-the-road-automotive-bioplastics/

กฎกระทรวงการขออนุญาตและการอนุญาตผลิต นําเข้าส่งออก จําหน่าย หรือมีไว้ในครอบครองซึ่งยาเสพติดให้ โทษในประเภท 5 เฉพาะกัญชง (Hemp) พ.ศ. 2563. ราชกิจจานุเบกษา 30 ธันวาคม 2563. ราชกิจจานุเบกษา เล่ม 137 ตอนที่ 107 ก.

มูลนิธิสถาบันพัฒนาวิสาหกิจขนาดกลางและขนาดย่อมบทสรุปผู้บริหารโครงการส่งเสริมและพัฒนา อุตสาหกรรมเฮมพ์ อย่างสร้างสรรค์แบบครบวงจร. การ ประชุมระดมความคิดเห็นแนวทางการใช้ประโยชน์จากกัญชง. 2562

SAWPAN, M.A., K.L. PICKERING and ALAN FERNYHOUGH. Hemp fibre reinforced poly (lactic acid) composites. Advanced Materials Research.2007, 29-30, 337-340.

AL-MULLA, E.A.J., W.Md.Z.W. YUNUS, N.A.B. IBRAHIM and M.Z.Ab. RAHMAN. Properties of epoxidized palm oil plasticized polytlactic acid. Journal of Materials Science. 2010, 45, 1942– 1946

MARTINO, V.P., A. JIMENEZ and R.A. RUSECKAITE. Processing and characterization of poly (lactic acid) films plasticized with commercial adipates. Journal of Applied Polymer Science. 2009,112(4), 2010-2018.

WIMMER, R., B. STEYRER, J. WOESS, T. KODDENBERG and N. MUNDIGLER. 3D printing and wood. International Conference Wood Science Rumania. 10th edition, 2015, pp. 145-150.

OU-YANG, Q., B. GUO and J. XU. Preparation and characterization of poly (butylene succinate) polylactide blends for fused deposition modeling 3D printing. ACS Omega. 2018, 3(10), 14309-14317.

CHIULAN, I., A. FRONE, C. BRADABUR and D.M. PANAITESCU. Recent advances in 3D printing of aliphatic polyesters. Bioengineering (Basel). 2017, 5(1), 2.

KARIZ, M., M. SERNEK, M. OBUCINA and M.K. KUZMAN. Effect of wood content in FDM filament on properties of 3D printed parts. Materials Today Communications. 2018, 14, 135-140.

GUO, R., Z. REN, H. BI, Y. SONG and M. XU. Effect of toughening agents on the properties of poplar wood flour/poly (lactic acid) composites fabricated with fused deposition modeling. European Polymer Journal. 2018, 107, 34-45.

RASSELET, D., A.S. CARO-BRETELLE, A. TAGUET and JOSE-MARIE LOPEZ-CUESTA. Reactive compatibilization of PLA/PA11 blends and their application in additive manufacturing. Materials. 2019, 12(3), 485.

SAWPAN, M.A., K.L. PICKERING and ALAN FERNY HOUGH. Characterisation of hemp fibre reinforced Poly(Lactic Acid). International Journal of Materials and Product Technology. 2009, 36(1-4).

SHIBATA, M., K. OZAWA, N. TERAMOTO, R. YOSOMIYA and H. TAKEISHI. Biocomposites made from short abaca fiber and biodegradable polyesters. Macromolecular Materials and Engineering. 2003, 288(1), 35-43.

SERIZAWA, SHIN., KAZUHIKO INOUE and MASATOSHI IJI. Kenaf-fiber-reinforced poly (lactic acid) used for electronic products. Journal of Applied Polymer Science. 2006, 100(1), 618-624.

HUDA, M.S., A.K. MOHANTY, L.T. DRZAL, M. MISRA, K. WILLIAMS and D.F. MIELEWSKI. Mechanical and thermo-mechanical studies of poly (lactic acid) PLA/talc/recycled newspaper fiber hybrid composites. Atlanta, GA, United States, 2005, pp. 469.

MWAIKAMBO, L.Y. and M.P. ANSELL. Mechanical properties of alkali treated plant fibres and their potential as reinforcement materials. I. Hemp fibres. Journal of Materials Science. 2008, 41, 2483-2496.

LI, D., Y. JIANG, S. LV, X. LIU, J. GU, Q. CHEN and Y. ZHANG. Preparation of plasticized poly (lactic acid) and its influence on the properties of composite materials. PLOS ONE. 2018, 13(3), e0193520.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2021 Bulletin of Applied Sciences

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.