ผลกระทบของอัตราความเครียดต่อการวัดสมบัติทางกลของเหล็กเส้นเสริมคอนกรีต

DOI:

https://doi.org/10.60136/bas.v8.2019.268คำสำคัญ:

อัตราความเครียด, ความไวต่ออัตราความเครียด, สมบัติทางกลบทคัดย่อ

ในการทดสอบแรงดึง มาตรฐานการทดสอบส่วนมากระบุอัตราความเครียดที่ควรปฏิบัติ เนื่องจากวัสดุจะเกิดการครากที่ระดับความแข็งแรงที่แตกต่างและมีความไวค่อนข้างต่ำต่ออัตราความเครียดสำหรับความต้านแรงดึง วัสดุที่ทดสอบตรงตามมาตรฐานการทดสอบควรให้ค่าความแข็งแรงที่เท่ากันโดยไม่คำนึงว่าห้องปฏิบัติการทดสอบใดทำการทดสอบ ความแข็งแรงของวัสดุที่แสดงอาจขึ้นอยู่อัตราความเครียดที่ใช้ จึงมีคำถามเกี่ยวข้องกับผลของอัตราความเครียดว่าความแตกต่างของอัตราความเครียดมีอิทธิพลต่อสมบัติทางกลของวัสดุที่ทำการทดสอบหรือไม่

ตามมาตรฐานการทดสอบเหล็กเส้นเสริมคอนกรีต ค่าสมบัติทางกลต่ำสุดที่แน่นอน เช่น ความเค้นคราก ความต้านแรงดึง ความยืด การลดทอนพื้นที่ และมอดุลัสยืดหยุ่น เป็นที่ต้องการทราบ ดังนั้น ห้องปฏิบัติทดสอบต้องดำเนินการเพื่อให้ได้มาข้อมูลสมบัติทางกลที่น่าเชื่อ ความน่าเชื่อสูงสุดของข้อมูลสมบัติทางกล นำสู่ความถูกต้องแม่นยำในการใช้งาน ทำให้สามารถหลีกเลี่ยงความเสียหายที่รุนแรง การทำให้เกิดการเสียชีวิต หรือค่าใช้จ่ายที่สูงในการซ่อมบำรุง

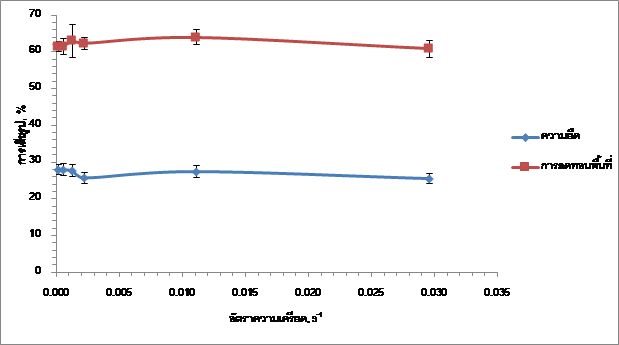

การวิจัยนี้ต้องการศึกษาผลกระทบของอัตราความเครียดที่แตกต่าง (0.000185 s-1, 0.000555 s-1, 0.001296 s-1, 0.002222 s-1, 0.011111 s-1, และ 0.02963 s-1) ต่อค่าสมบัติทางกล (ความเค้นคราก ความต้านแรงดึง ความยืด และการลดทอนพื้นที่) โดยพิจารณาจากความไวต่ออัตราความเครียด () ผลการวิจัยแสดงให้เห็นว่าอัตราความเครียดที่แตกต่างมีผลกระทบต่อค่าสมบัติทางกล ความต้านแรงดึงมีแนวโน้มลดลง (ประมาณ 13 MPa) และความเค้นครากมีแนวโน้มเพิ่มขึ้น (ประมาณ 19 MPa) เมื่ออัตราความเครียดเพิ่มขึ้น สอดคล้องกับความไวต่ออัตราความเครียดสำหรับความต้านแรงดึง m=-0.0024 และความไวต่ออัตราความเครียดสำหรับความเค้นคราก m=0.0045 การเพิ่มขึ้นของอัตราความเครียดมีผลต่อความเค้นครากมากกว่าความต้านแรงดึง นอกจากนั้น ความเค้นคราก (ประมาณ ±30 MPa และ ±47 MPa ตามลำดับ) และความต้านแรงดึง (ประมาณ ±60 MPa และ ±82 MPa ตามลำดับ) มีค่าความไม่แน่นอนสูงกว่าที่อัตราความเครียดต่ำสุดและอัตราความเครียดสูงสุด นอกจากนั้น ความยืดมีแนวโน้มลดลง (ประมาณ 3%) และการลดทอนพื้นที่มีแนวโน้มเพิ่มขึ้นเล็กน้อย (ประมาณ 1%) เมื่ออัตราความเครียดเพิ่มขึ้น สอดคล้องกับความไวต่ออัตราความเครียดสำหรับความยืด m=-0.0341 และความไวต่ออัตราความเครียดสำหรับการลดทอนพื้นที่ m=0.0032 เมื่ออัตราความเครียดเพิ่มสูงขึ้น ความยืดลดลงอย่างมาก แตกต่างกับการลดทอนพื้นที่ที่เพิ่มขึ้นในปริมาณน้อยมากหรือแทบไม่เปลี่ยนแปลง นอกจากนั้น ความยืด (ประมาณ ±0.2%) และการลดทอนพื้นที่ (ประมาณ ±0.3%) มีค่าความไม่แน่นอนเพิ่มสูงขึ้นเล็กน้อย เมื่ออัตราความเครียดเพิ่มสูงขึ้น

เอกสารอ้างอิง

HUH, J., H. HUH and C. S. LEE. Effect of strain rate on plastic anisotropy of advanced high strength steel sheets. International Journal of Plasticity. May, 2013, 44, 23-46.

LI, X., J. CHEN, L. YE, W. DING and P. SONG, Influence of strain rate on tensile characteristics of SUS304 metastable austenitic stainless steel. ACTA Metallurgica Sinica. 2013, 26(6), 657-662.

ANDERSON, D., S. WINKLER, A. BARDELCIK and M. J. WORSWICK. Influence of triaxiality and strain rate on the failure behaviour of a dual-phase DP780 steel. Materials & Design. August, 2014, 60, 198-207.

BLAZ, L. and E. EVANGELISTA. Strain rate sensitivity of hot deformed Al and AlMgSi alloy. Materials Science and Engineering: A. 1996, 207(2), 95-201.

HADIANFARD, M. J., R. SMERD, S. WINKLER and M.WORSWICK. Effects of strain rate on mechanical properties and failure mechanism. Materials Science and Engineering: A. 2008, 492(1-2), 283-292.

LUO, J., M. Li, W. Yu and H. Li. The variation of strain rate sensitivity exponent and strain hardening exponent in isothermal compression of Ti-6Al-4V alloy. Materials & Design. 2010, 31(2), 741-748.

LICHTENFELD, J. A., M. C. MATAYA and C. J. VAN TYNE. Effect of strain rate on stress-strin behavior of alloy 309 and 304L austenitic stainless stainless steel. Metallurgical and Materials Transactions: A. 2006, 37(1), 147-161.

ZHOU, F., J. N. WANG and J. S. LIAN. An investigation of the plastic failure of spheroidized steels. Materials Science and Engineering: A. 2002, 332(1-2), 117-122.

FAN, G. J., L. F. FU, H. CHOO, P. K. LIAW and N. D. BROWNING. Uniaxial tensile plastic deformation and grain growth of bulk nanocrystalline alloys. Acta Materialia. 2006, 54(18), 4781-4792.

NILSSON, K. F and V. VOKAL. Analysis of ductile cast iron tensile tests to relate ductility variation to casting defects and material microstructure, Materials Science and Engineering: A. 2009, 502(1-2), 54-63.

BACHA, A., D. DANIEL and H. KLOCKER. On the determination of true stress triaxiality in sheet metal. Journal of Materials Processing Technology. 2007, 184(1-3), 272-287.

PUTATUNDA, S. K. Fracture toughness of a high carbon and high silicon steel. Materials Science and Engineering: A. 2001, 297(1–2), 31-43.

ELWAZRI, A. M., P. WANJARA and S. YUE. The effect of microstructural characteristics of pearlite on the mechanical properties of hypereutectoid steel. Materials Science and Engineering: A. 2005, 404(1–2), 91-98.

ดาวน์โหลด

เผยแพร่แล้ว

รูปแบบการอ้างอิง

ฉบับ

ประเภทบทความ

สัญญาอนุญาต

ลิขสิทธิ์ (c) 2022 วารสารวิทยาศาสตร์ประยุกต์ กรมวิทยาศาสตร์บริการ

อนุญาตภายใต้เงื่อนไข Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.