Analysis of damage in steel bar for reinforced concrete deformed at varied strain rates by continuum damage mechanism

DOI:

https://doi.org/10.60136/bas.v8.2019.258Keywords:

Damage evolution, Elastic modulus, Strain rateAbstract

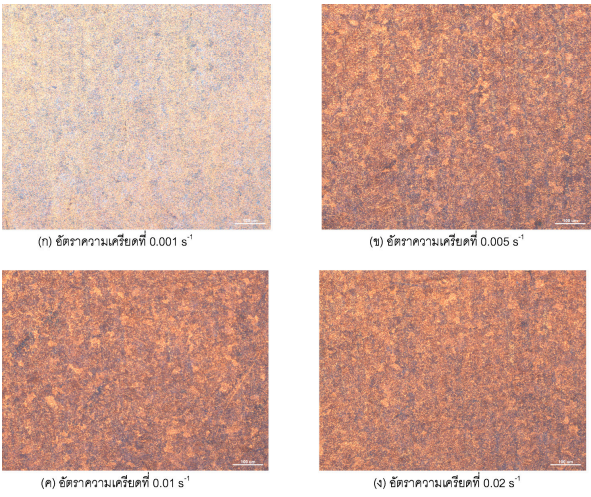

This research study aimed to examine damage evolution in steel bar for reinforced concrete by continuum damage mechanism from and throughout deforming process at varied strain rates from 0.001 s-1, 0.005 s-1, 0.01 s-1 to 0.02 s-1. From the research study, the increase of the strain rates in the beginning (0.001 s-1 to 0.01 s-1) had a significant effect on the development of the damage, approximately 0.33 and 0.18. In other words, the damage rate greatly increased in the initial stage when the stain rate increased. In the later stage, the rising of the strain rates from 0.01 s-1 to 0.02 s-1 had a slighter effect on the development of the damage, approximately 0.17 and 0.11. In other words, the damage rate increased lower when the strain rate rose additionally.

References

DARRAS, B. M., F. ABED, S. PERVAIZ and A. ABDUL-LATIF. Analysis of damage in 5083 aluminum alloy deformed at different strain rates. Materials Science and Engineering: A. 2013, 568(7),143-149.

KRAJCINOVIC, D. and S. MASTILOVIC. Some fundamental issues of damage mechanics. Mechanics of Materials. 1995, 21(3), 217-230.

STRAFFELINI, G. and A. MOLINARI. Evolution of tensile damage in porous iron. Materials Science and Engineering: A. 2002, 334(1–2), 96-103.

LIAO, I., Y. SUN, J. LIU and W. ZHANG. Applicability of damage models for failure analysis of threaded bolts. Engineering Fracture Mechanics. 2011, 8(3), 514-524.

BONORA, N., D. GENTILE, A. PIRONDI and G. NEWAZ. Ductile damage evolution under triaxial state of stress: theory and experiments. International Journal of Plasticity. 2005, 21(5), 981-1007.

DIAO, X. A statistical equation of damage evolution. Engineering Fracture Mechanic. 1995, 52(1), 33-42.

ALVES, M., J. YU and N. JONES. On the elastic modulus degradation in continuum damage mechanics. Computers & Structures. 2000, 76(6), 703-712.

BONORA, N. and G. M. NEWAZ. Low cycle fatigue life estimation for ductile metals using a nonlinear continuum damage mechanics model. International Journal of Solids and Structures. 1998, 35(6), 1881-1894.

VOYIADJIS, G. Z. and P. I. KATTAN. How a singularity forms in continuum damage mechanics. Mechanics Research Communications. January, 2014, 55, 86-88.

ZHOU, F., J. N. WANG and J. S. LIAN. An investigation of the plastic failure of spheroidized steels. Materials Science and Engineering: A. 2002, 332(1-2), 117-122.

LIU, J. H., X. Y. HAO, G. L. LI and G. S. LIU. Microvoid evaluation of ferrite ductile iron under strain. Materials Letters. 2002, 56(5), 748-755.

ORSINI, V. C. and M. A. ZIKRY. Void growth and interaction in crystalline materials. International Journal of Plasticity. 2001, 17(10), 1393-1417.

THOMSON, R. D. and J. W. HANCOCK. Ductile failure by void nucleation, growth and coalescence. International Journal of Fracture. 1984, 26(2), 99-112.

IBIJOLA, E. A. On some fundamental concepts of continuum damage mechanics. Computer Methods in Applied Mechanics and Engineering. 2002, 191(13-14), 1505-1520.

BLAZ, L. and E. EVANGELISTA. Strain rate sensitivity of hot deformed Al and AlMgSi alloy. Materials Science and Engineering: A. 1996, 207(2), 195-201.

HADIANFARD, M. J., R. SMERD, S. WINKLER and M. WORSWICK. Effects of strain rate on mechanical properties and failure mechanism of structural Al-Mg alloys. Materials Science and Engineering: A. 2008, 492(1-2), 283-292.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Bulletin of Applied Sciences

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.