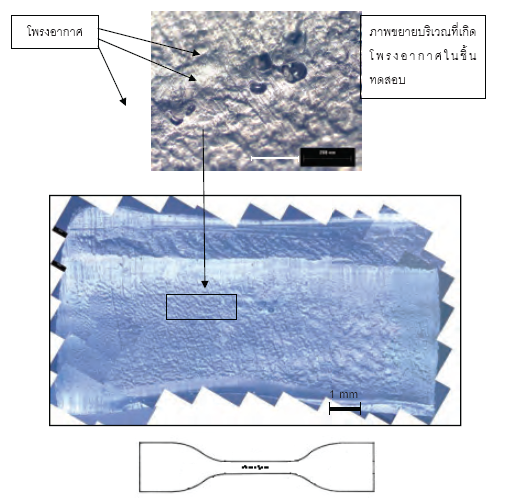

Troubleshooting of defect formation in injection-moulded thermoplastic tensile specimens by optical microscopy technique

DOI:

https://doi.org/10.60136/bas.v3.2014.243Keywords:

Blister, Defect, Polyethylene, Polypropylene, VoidAbstract

Voids and blisters often appear in a dumbbell-shaped tensile specimens fabricated by thermoplastic injection molding process. In this study, polypropylene and high density polyethylene were selected to investigate the effects of these defects on tensile properties; i.e., maximum load, tensile strength and elongation at break. From the results of tensile properties for both materials, it was found that the maximum load and tensile strength of specimens without defects were higher than those with defects approximately 2%. As for the elongation at break for both materials, specimens without defects provided final length greater than those with defects significantly (approximately 80%). In addition, the cross-sectional area was observed by an optical microscope, showing that polypropylene specimens contained voids where those of polyethylene had blister defects. This information was then employed to determine the troubleshooting of defect formation in the polymeric specimens fabricated via injection molding

References

CENTRAL INSTITUTE OF PLASTICS ENGINEERING AND TECHNOLOGY. Plastics industry-statistics (Online). (viewed 7 January 2012). Available from: http://ipet.gov.in/plastics_statistics.html.

สมเจตน์ พัชรพันธ์. ข้อบกพร่องในชิ้น งานพลาสติกที่ผ่านกระบวนการฉีดขึ้นรูป: สาเหตุและ แนวทางการแก้ไข. วิศวกรรมสาร มก., 2552, 22(69), 91-104

Viewmold. Injection molding defects (Online). (viewed 23 May 2014). Available from: http://www.viewmold.com/Injection%20Mold%20Management/Injection%20molding%20defects.html.

ชัยยาฉุยฉาย. การออกแบบการทดลองแก้ไข ปัญหาการฉีดงานพลาสติกในงานผลิต ชิ้นส่วนรถจักรยานยนต์ วิทยานิพนธ์หลักสูตรปริญญา วิศวกรรมศาสตรมหาบัณฑิต บัณฑิตวิทยาลัย มหาวิทยาลัยศิลปากร, 2552

Industrial computed tomography (Online). (viewed 23 May 2014). Available from: http://en.wikipedia.org/wiki/Industrial_CT_scanning.

Plastics Technology (Online). September 2008, (viewed 23 May 2014). Industrial CT scanning speeds mold qualification. Available from: http://www.ptonline.com/articles/industrial-ct-scanningspeeds-mold-qualification.

AMERICAN SOCIETY FOR TESTING AND MATERIALS. Standard test method for tensile properties of plastics. D638-2010. In Annual book of ASTM standard : Plastics. Vol. 08.01. West Conshohocken : ASTM, 2010, pp.50-65.

MICHAELI, W., et al. Training in injection molding. Munich : Hanser Publishers, 1995.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Bulletin of Applied Sciences

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.