Properties of pineapple-leaf fibers after chemical treatments

DOI:

https://doi.org/10.60136/bas.v7.2018.226Keywords:

Pineapple-leaf, Fiber, TreatmentAbstract

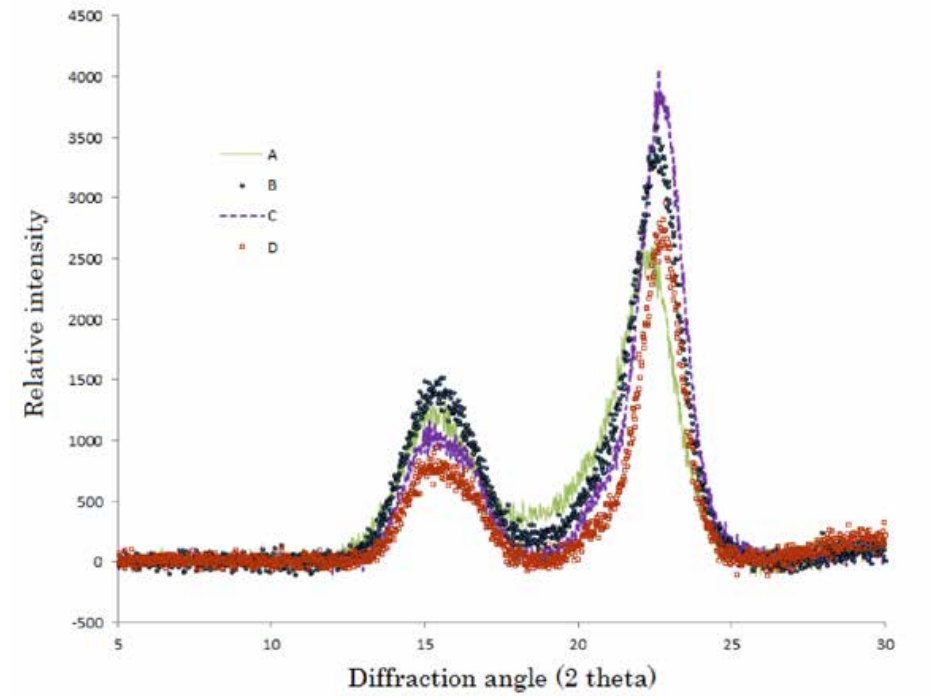

This research studied properties of pineapple-leaf cellulose fibers after chemical treatments using various ratios of a mixture of sodium hydroxide and ethanol extracting solvent at 95°C and a treatment time duration between 2-4 hr. The treated fibers were then investigated using FTIR, TGA, XRD and SEM techniques. FTIR spectra indicated that non-cellulosic components were effectively eliminated. DTG thermograms showed that the temperature at the maximum weight loss of a treated fiber was closed to that of commercial available cellulose. In addition, XRD results indicated that the crystallinity index of the treated fiber was higher 56%, when compared to that of untreated fiber. Furthermore, SEM images revealed that the treated fibers were defibrillated from fiber bundles

References

BISMARCK, A., S. MISHRA and T. LAMPKE. Plant fibers as reinforcement for green composites. In Mohanty, AK., Misra, M., and Drzal, LT. (Ed.). Natural Fibers, Biopolymers, and Biocomposites. New York: Taylor & Francis, 2005, pp. 37-108.

PUJARI, S., A. RAMAKRISHNA and MS. KUMAR. Comparison of jute and banana fiber Composites: A review. International Journal of Current Engineering and Technology. 2014, 121-126.

วิทยา ปันสุวรรณ. การวิเคราะห์องค์ประกอบทางเคมี ของวัตถุดิบที่ไม่ใช่ไม้สําหรับอุตสาหกรรมเยื่อและกระดาษ การ ประชุมวิชาการของมหาวิทยาลัยเกษตรศาสตร์ ครั้งที่ 36. 3-5 กุมภาพันธ์ 2541. กรุงเทพฯ.

OKUBO, K., T. Fujii and Y. Yamamoto. Development of bamboo-based composites and their mechanical properties. Composites: part A. 2004, 35(3), 377-383.

RAJ, G., et al. Interfacial studies of polylactic acid (PLA)/flax biocomposite: from model surface to fibre treatment [online]. [viewed 10 December 2016]. Available from: http://iccm-central.org/Proceedings/ ICCM17proceedings/Themes/Materials/NATURAL%20 FIBRE%20COMPOSITES/D9.2%20Raj.pdf

SAHIN, H.T. Base-catalyzed organosolv pulping of jute. Journal of Chemical Technology and Biotechnology. 2003, 78, 1267-1273.

SINGH, K., et al. Determination of composition of cellulose and lignin mixtures using thermogravimetric analysis (TGA), 15th North American Waste to Energy Conference, May 21-23, 2007, Miami, Florida USA.

YANG, H., et al. Characteristic of hemicellulose, cellulose and lignin pyrolysis. Fuel. 2007, 86, 1781-1788.

KUSUMATTAQIIN, F. Preparation and characterization of microcrystalline cellulose (MCC) by acid hydrolysis using microwave assisted method from cotton wool. Macromolecule Symposium. 2015, 354, 35-41.

AKGUL, M. and A. TOZLUOGLU. Alkaline-ethanol pulping of cotton stalks. Scientific Research and Essays. 2010, 5(10), 1068-1074.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Bulletin of Applied Sciences

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.