Development of force control equipment for paper crush testers calibration

DOI:

https://doi.org/10.60136/bas.v10.2021.152Keywords:

Ring crush tester machine, Compression calibration, Load cellAbstract

Mechanical properties of paper packaging are one of the indicators for the capabilities of the final products. According to the consistency, accuracy, and effectiveness of the testing equipment, it needs to be calibrated with the standard calibration equipment to ensure that the testing equipment could be worked properly and efficiency. In addition, the repetitiveness of the calibration also indicates the stability of the testing equipment. The ring crush tester is used to determine the ring crush resistance of a paper strip formed into a ring with a standardized length and width. This test is performed corresponding to TAPPI 818, ISO 12192 and TISI 321 standard. The main calibration equipment are load cell and monitor, which the calibrated person needs to adjust the force of the load cell himself which the value of the adjusted force needs to be exactly equal to the given standard. As a consequence of this adjustment, too much time of adjustment is taken, and the force of the load cell is not accurate, imprecise and various leading to the inaccurate calibration.

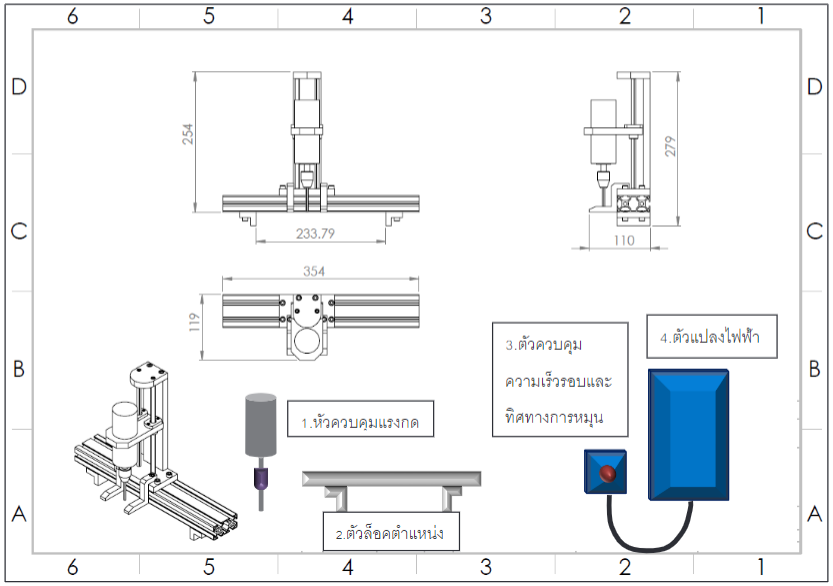

In this work, the add-on equipment for controlling the force adjustment of the load cell is developed using the gearing ratio and the motor. The results show the increase of stability of the force adjustment, in other words, the adjusted force is 2-8 newtons closer to the given standard, 20-25% of lower adjusted time taken, and 10.4-37.5% lower of uncertainty. The repeatability and reproducibility also 19% and 48% improved, respectively. Furthermore, this add-on equipment is controlled by rotational rate and the linear guide way, which leads to the higher precision and accuracy.

References

THE TECHNICAL ASSOCIATION OF THE PULP AND PAPER INDUSTRY. TAPPI 818 cm-07. Ring crush of paperboard. 2007.

INTERNATIONAL ORGANIZATION FOR STANDARD IZATION. ISO 12192:2011. Paper and board- Determination of compressive strength-Ring crush method. 2011.

สํานักงานมาตรฐานผลิตภัณฑ์อุตสาหกรรม. มอก.321-2560. กระดาษลูกฟูก. 2560.

จรวย ธงไชย. การศึกษาอิทธิพลของตัวแปรที่มีผลต่อความต้านแรงกดของกระดาษลูกฟูก. กรุงเทพฯ: กรมวิทยาศาสตร์บริการ. 2542. 64 หน้า.

INTERNATIONAL ORGANIZATION FOR STANDARD IZATION. ISO 13820:2014. Paper, board and corrugated fibreboard-Description and calibration of compression-testing equipment. 2014.

โหลดเซลล์ (Load Cell) คืออะไร ราคาเท่าไหร่ [ออนไลน์]. 2562 [อ้างถึงวันที่ 2 พฤษภาคม 2562] เข้าถึงจาก http://www.SV5-en.com/load-CelL/

กฤษ เฉยไสย. พื้นฐานการควบคุมมอเตอร์ (เอกสารการสอน), คณะวิศวกรรมศาสตร์ มหาวิทยาลัยขอนแก่น, 2547.

ปราณี หลาเบ็ญสะ. การหาคุณภาพของเศรื่องมือวัดและ ประเมินผล (เอกสารการสอน), คณะครุศาสตร์มหาวิทยาลัยราชภัฏยะลา, 2559.

UNITED KINGDOM ACCREDITATION SERVICE. M3003. The expression of uncertainty and confidence in measurement. Edition 4. Middle sex: UKAS, October 2019.

ENGINEERED SOFTWARE, INC. Repeatability and reproducibility. [online]. [viewed 12 January 2021]. Available from: http://www.engineeredsoftware.com/papers/msa_rr.pdf

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2021 Bulletin of Applied Sciences

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.