Glass batch development for pot furnace

DOI:

https://doi.org/10.60136/bas.v4.2015.290Keywords:

Soda-lime glass, Pot furnace, BatchAbstract

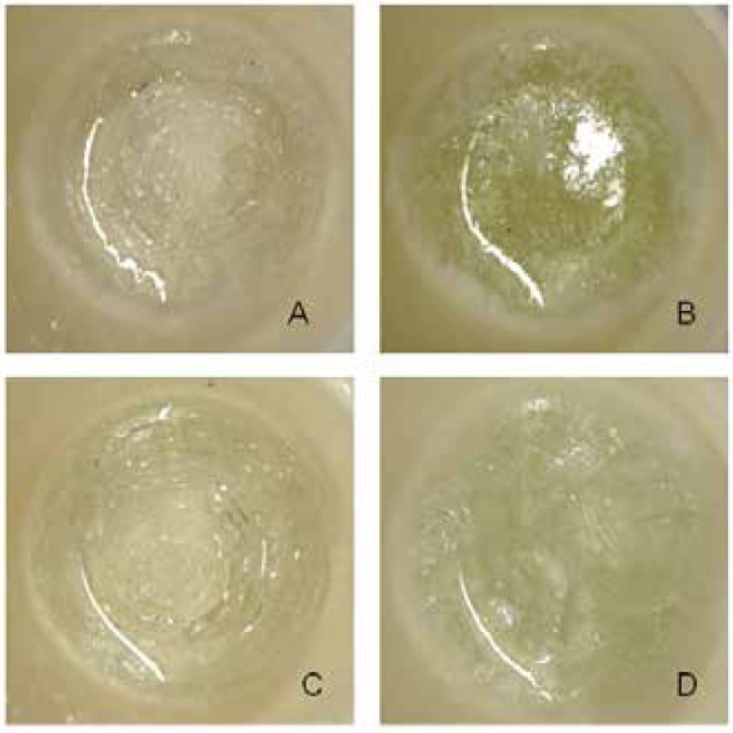

This research is to develop glass formula for pot furnace. The formula is modified from a prototype soda-lime glass which has low silica content. The low silica glass can be melted easier than the high silica content glass. The developed glass formula by using local raw materials can be melted at temperature below 1,400 °C. The glass formula is silica (SiO2) 68%, alkaline (Na2O+K2O) 19%, alkaline earth (CaO+MgO) 9% with barium oxide (BaO) 2% and zinc oxide (ZnO) 2% in weight. The glass properties are closed to the reference glass which has the viscosity and the coefficient of thermal expansion suitable for blowing process and can be applied for the industrial scale glass production.

References

พรายพล คุ้มทรัพย์, สถานการณ์พลังงานโลก: วิกฤตการณ์น้ำมันครั้งที่ 3. การสัมมนาประจําปี เรื่องสถานการณ์พลังงานโลกและการปรับตัวของไทย คณะเศรษฐศาสตร์ มหาวิทยาลัยธรรมศาสตร์ 2551, หน้า 1-32.

กรมพลังงานทดแทนและอนุรักษ์พลังงาน, 2551. เอกสารเผยแพร่โครงการศึกษาเกณฑ์การใช้พลังงานในอุตสาหกรรมอโลหะ [ออนไลน์]. อ้างถึงวันที่ 1 มีนาคม 2558]. เข้าถึงจาก: http://www2.dede.go.th/km berc/downloads/menu4/เอกสารเผยแพร่/คู่มือ/ 08%20 sec/09%20อุตสาหกรรมอโลหะ/อโลหะ .pdf

TOOLEY, F. V. The handbook of glass manufacture. 3rd ed. New York: Ashlee Publishing, 1984.

SHELBY, J. E. Introduction to glass science and technology. 2nd ed. Cambridge : The Royal Society of Chemistry, 2005.

MEECHOOWAS, E., et al. Improve melting efficency by Batch-to melt conversion. Procedia Engineering, 2012, 32, 956-961.

MEECHOOWAS, E., et al. Modified glass batch can have increased alumina content by using feldspar to improve glass properties. Suranaree J. Sci Technol., 2013, 20(4), 309-315.

MEECHOOWAS, E., K. TAPASA, and T. JITWATCHARAKOMOL. Alternative soda-lime glass batch to reduce energy consumption. Key. Eng. Mater., 2013, 545, 24-30.

MEECHOOWAS, E., et al. Low melting glass billets for pot furnace glass processing. Key. Eng. Mater., 2014, 608, 295-300.

CONRADT, R. The industrial glass-melting process. The SGTE casebook: Thermodynamics at work. 2nd ed. Cambridge : Woodhead Publishing, 2008, pp. 282-303.

TAPASA, K. and T. JITWATCHARAKOMOL. Thermodynamic calculation of exploited heat used in glass melting furnace. Procedia Engineering, 2012, 32, 969-975.

BRAY, C. Dictionary of Glass: Materials and Techniques. 2nd ed. Pennsylvania : University of Pennsylvania Press, 2001.

FLUEGEL, A. Glass viscosity calculation based on a global statistical modeling approach. Europ. J. Glass Sci. Technol. A, 2007, 48, 13-30.

VOGEL, W. Chemistry of glass. Westerville, Ohio : The American Ceramic Society, 1985.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Bulletin of Applied Sciences

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.