Natural rubber-based compound for rubber mold cleaning

DOI:

https://doi.org/10.60136/bas.v6.2017.208Keywords:

Natural rubber, Mold fouling, Rubber compoundAbstract

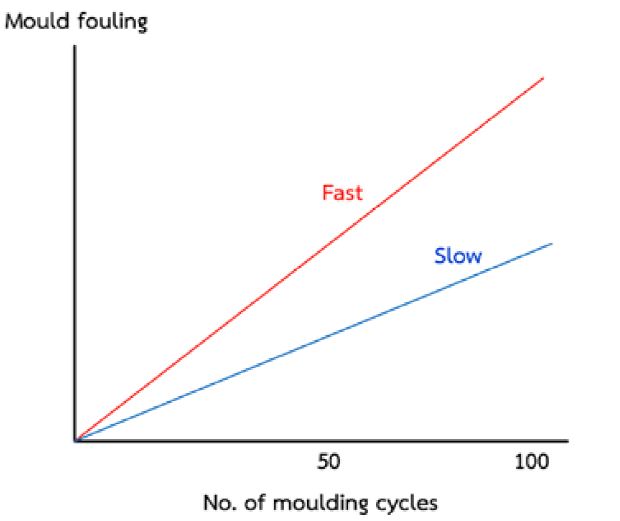

In the rubber processing industry, forming requires the molds which always become fouled for a certain period of time. These stains affect the quality of the products and the manufacturing costs. Therefore, the mold cleaning process is required. A plethora of methods are employed; for example, sand blasting, wire brushing, ultrasonic cleaning, and chemical cleaning. However, all of the previously mentioned approaches lead to complications with regard to removal of the mold from the heating press of the molding machine. In addition, the mold surfaces are prone to damage during disassembly and transit to a specific area for cleaning. This study presents a technique for cleaning molds while they remain in the curing press using the natural rubber-based compound. The effect of different amounts of cleaning agent in the compound was investigated. Other than various loadings of cleaning agent, it is found that the effectiveness of the mold cleaning depends on several factors; for example, type of curing agent, curing time and temperature.

References

VECCHIO, R.J.D. Molding. In: VECCHIO, R.J.D., ed. Fundamentals of Rubber Technology. Akron : Technical Consulting Services. 2003,pp. 129-150.

SOMMER, J.G., H.N. GROVER and P.SUMAN. In-place cleaning of rubber curing molds. Rubber Chem. Technol. 1976, 49(5), 1129-1141.

MENGES, G. and W. BENFER. Mould fouling in injection moulding of elastomers. Int. J. Polym. Sci. Technol. 1988, 11, T/1-T/7.

BAARLE, B.V. Mold fouling during rubber vulcanization. Rubber World. 2004, 38, 25-29.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Bulletin of Applied Sciences

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.