Study of optimization conditions for inorganic/organic film development coating on aluminum alloy A5083 for improving the corrosion resistance

DOI:

https://doi.org/10.60136/bas.v9.2020.206Keywords:

Hybrid sol-gel, Corrosion, Aluminium, Smart coatingAbstract

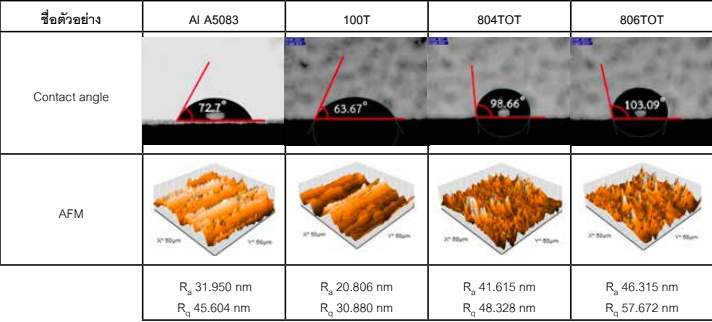

Aluminium alloy A5083 is commonly in for offshore industries since it has higher corrosion resistance by creating an oxide film protecting surfaces. However, the protective film can be destroyed under corrosive conditions like marine environment containing chloride and fluoride ions with alkalinity. To prevent the corrosion, an inorganic/organic film is applied by coating on aluminium alloy surfaces. The objective of this study was to investigate the effects of different organic precursors on corrosion resistance of the aluminium alloy under basic condition. The amounts of organic precursors and water contents in the hybrid inorganic/organic thin films coating were also studied. The hybrid films were prepared by sol-gel method containing an inorganic precursor, TEOS (Tetraethyl orthosilicate), and different organic precursors, namely AEAPS (3-(2-Aminoethyl aminopropyl trimethoxysilane), AMEO (3-Aminopropyl triethoxysilane), GPTMS (3-Glycidoxypropyl trimethoxysilane), MTMS (Methyl trimethoxysilane) and OTES (Octyltriethoxysilane). The ratios between inorganic and organic precursor were varied from 100:0, 90:10, 80:20, 70:30 and 60:40 by volume. In addition, the molar ratios of TEOS to water at different ratios, 1:1, 1:2, 1:3, 1:4, 1:5, 1:6, 1:7 and 1:8 were applied. The thin film named 806TOT consisted with TEOS:OTES ratio at 80:20 and TEOS to water ratio at 1:6 showed the highest hydrophobic property with 103.09±0.35º of contact angle. The potentiodynamic technique was employed to test corrosion resistance using 3.5 wt% NaCl. The results exhibited that 806TOT had the lowest rate of corrosion with 0.78 x 10-3 mm per year equivalent. This number is higher 50 times over aluminium alloy without coating.

References

YUE, J. and Y. CAO. Corrosion prevention by applied coatings on aluminium alloys in corrosive environments. International Journal of Electrochemical Science. 2015, 10, 5222 – 5237.

NAJAFABADI, A. H., R. MOZAFFARINIA, H RAHIMI, R. S. RAZAVI and E. PAIMOZD. Mechanical property evaluation of corrosion protection sol–gel nanocomposite coatings. Journal Surface Engineering. 2013, 29 (4), 249-254.

WANG, D. and G. P. BIERWAGEN. Sol-gel coatings on metals for corrosion protection, progress in organic coatings. Progress in Organic coatings. 2009, 64, 327-338.

SANTANA, I., A. PEPE, E. JIMENEZ-PIQUE, S. PELLICE and S. CERÉ. Silica-based hybrid coatings for corrosion protection of carbon steel.Part I: Effect of pretreatment with phosphoric acid. Surface and Coatings Technology. 2013, 236, 476-484.

PURCAR, V., O. L. CINTEZA, M. GHIUREA, A. BALAN, S. CAPRARESCU and D. DONESCU. Influence of hydrophobic characteristic of organo-modified precursor on wettability of silica film. Bulletin of Materials Science. 2014, 37(1),107-115.

AMERICAN SOCIETY FOR TESTING AND MATERIALS. ASTM G102-89.Standard practice for calculation of corrosion rates and related information from electrochemical measurements. 1989.

AMERICAN SOCIETY FOR TESTING AND MATERIALS. ASTM G1. Standard practice for preparing, cleaning, and evaluating corrosion test specimens.

BI, P., H. LI, G. ZHAO, M. RAN, L. CAO, H. GUO and Y. XUE. Robust super-hydrophobic coating prepared by electrochemical surface engineering for corrosion protection. Coatings, 2019, 9, 452.

MUSGO, J., J. C. ECHEVERRÍA, J. ESTELLA, M. LAGUNA and J. J.GARRIDO. Ammonia-catalyzed silica xerogels: Simultaneous effects of pH, synthesis temperature, and ethanol:TEOS and water:TEOS molar ratios on textural and structural properties. Microporous and Mesoporous Materials, 2009, 118(1–3), 280-287.

WIDATI, A. A., N. NURYONO and I. KARTINI. Water-repellent glass coated with SiO2–TiO2–methyltrimethoxysilane through sol–gel coating. AIMS Materials Science. 2019, 6(1),10–24.

WANG, S. and S. LUO, Fabrication of transparent superhydrophobic silica-based film on a glass substrate. Applied Surface Science. 2012, 258, 5443– 5450.

GEILS, J., G. PATZELT and A. KESEL. The larger the contact angle, the lower the adhesion?. Conference: Bionik: Patente aus der Natur. Innovationspotenziale für Technologieanwendungen 9. Bremer Bionik-Kongress, Bremen, Germany, January 2019.

SUROWSKA, B., M.OSTAPIUK, P.JAKUBCZAK and M. DROŹDZIEL. The durability of an organic–inorganic sol–gel interlayer in Al-GFRP-CFRP laminates in a saline environment. Materials (Basel). 2019, 12(15), 2362.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Bulletin of Applied Sciences

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.