Development of test method for determination of leadin lead-free solderusing inductively coupled plasma optical emission spectrometry

DOI:

https://doi.org/10.60136/bas.v3.2014.184Keywords:

Method Validation, Inductively Coupled Plasma Optical Emission Spectrometry, Lead-Free SolderAbstract

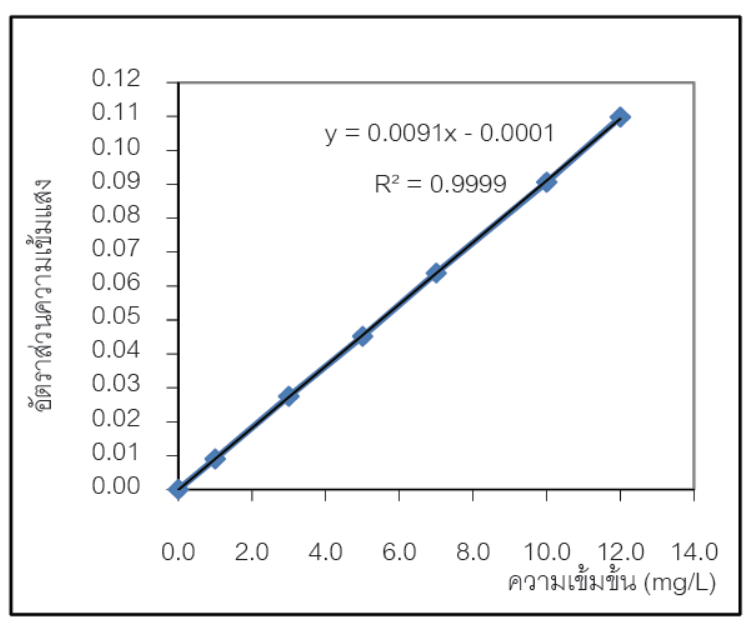

Lead-free solder is material developed in order to replace original solder in electric and electronic Industries which mainly contains tin and lead. To use lead-free solder. It is necessary to analyze six hazardous substances according to RoHS directive to ensure that the lead-free solder contains contaminants in products under the limits of this directive which, in case of lead, its content shall not be more than 1000 ppm. For analysis to ensure that lead-free solder used contains regulated substances under the limits, two standard test methods can be used which are International Standard IEC 62321-5: 2013-edition or Japanese Industrial Standard JIS Z 3910: 2008. Both standard methods employ wet digestion using concentrated acids and heating on hotplate. These digestion methods consume more acid content and can cause air pollutant. Development of new sample digestion using closed system such as microwave digestion can reduce amount of acids used and pollutant. This study focused on reducing mixed acids and digesting sample by microwave digestion. After obtaining optimized condition for sample digestion, the process of the method validation for the determination of lead content in lead-free solder using Inductively coupled plasma optical emission spectrometer was conducted to proof of certain performance characteristics. From the study, it was found that there is no matrix effect. While bias and precision studies showed that the percentage of recovery and relative standard deviations were in good agreement with the criteria. Then data from the bias and the precision study could be used to estimate measurement of uncertainty of the method. The expanded uncertainty of lead in lead-free solder by this method was less than ± 15%, at the confidence level of 95 %. The estimation of measurement uncertainty obtained was corresponding to the target uncertainty. Therefore, it can be concluded that this validated method was fit for intended use and laboratory can use this validated method to provide testing service for customers further.

References

INTERNATIONAL ELECTROTECHNICAL COMMISSION. IEC 62321-5: 2013. Determination of certain substances in electrotechnical products-Part 5: Cadmium, lead and chromium in polymers and electronics and cadmium and lead in metals by AAS, AFS, ICP-OES and ICP-MS.

JAPANESE INDUSTRIAL STANDARD. JIS Z 3910: 2008, Methods for chemical analysis of solder.

EURACHEM. Eurachem Guide: The Fitness for purpose of analytical methods, A Laboratory guide to method validation and related topics. London : Laboratory of the government chemist, 1998

BARWICK. V. J., and S. L. R. ELLISON. VAM Project 3.2.1 Development and Harmonisation of Measurement Uncertainty Principles Part (d): Protocol for uncertainty evaluation from validation data, Version 5.1, January 2000.

EURACHEM/ CITAC. Guide CG 4: Quantifying Uncertainty in Analytical Measurement, 3rd ed. London: Laboratory of the government chemist, 2012.

MILLER, J.C., and J.N. MILLER. Statistics for analytical Chemistry. 5th ed. England : Person Education Limited, 2005.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Bulletin of Applied Sciences

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.