Development of compound rubber formula for electron beam vulcanization

DOI:

https://doi.org/10.60136/bas.v11.2022.130Keywords:

electron beam, e-beam dose, rubber vulcanization, sensitizerAbstract

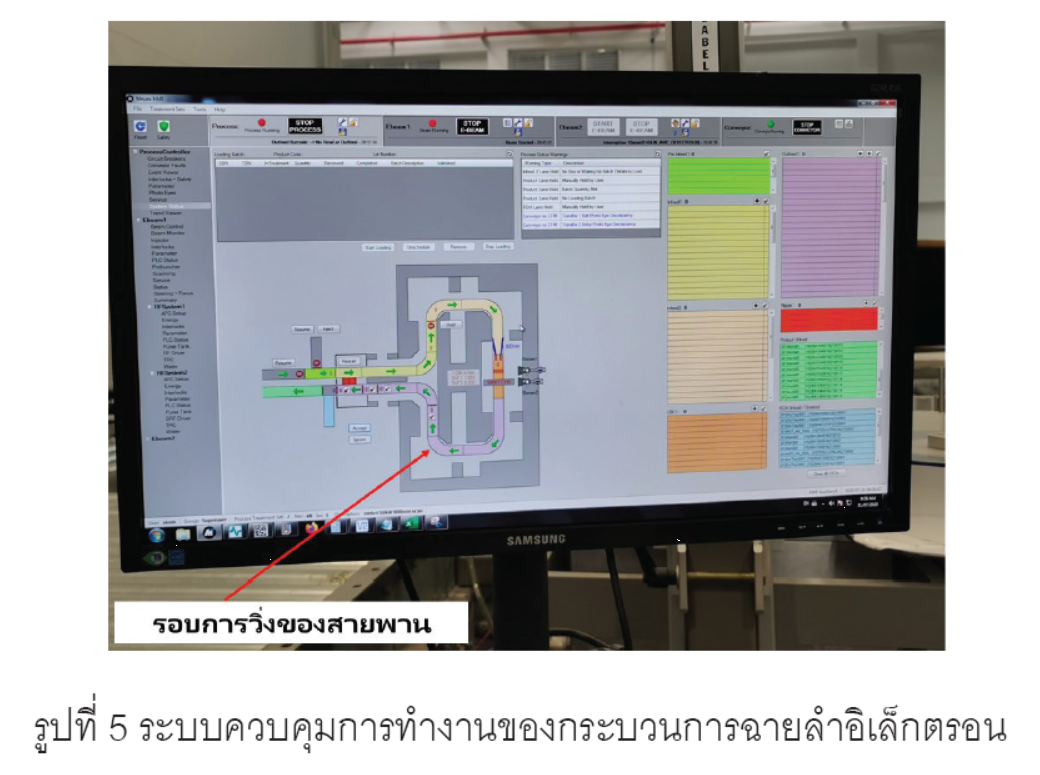

The electron beam (E-Beam) vulcanization system is a high-speed vulcanization technique, which offers products with better homogeneity than those obtained from sulfur vulcanization system. In addition, E-Beam vulcanization requires less chemicals than sulfur vulcanization, thus leaving fewer chemical residues and therefore making it an environmentally friendly process. In this study, Standard Thai Rubber (STR) were used to develop rubber compound formulae for electron beam vulcanization. Two types of sensitizer; n-Butyl acrylate (n-BA) and trimethylolpropane trimethacrylate (TMPT) along with their varied amount (3 and 5 phr) were studied and compared to the physical properties (hardness, tensile strength, elongation at break and tension set) of the rubber sheets vulcanized with conventional sulfur system. The study of the optimum dose for electron beam irradiation for rubber vulcanization was carried out using an electron beam accelerator with accelerated energy of 10 million electron volts (MeV) at four different doses: 50 kGy, 100 kGy, 150 kGy and 200 kGy. From this study, it was found that the formulation containing 5 phr TMPT sensitizer, vulcanized with the electron beam at 200 kGy was suitable for vulcanizing rubber products which require low tension set. However, the physical properties of the rubber obtained from this study were slightly lower than those prepared from sulfur-vulcanized system.

References

ยางพารา [ออนไลน์]. กุมภาพันธ์ 2564 เข้าถึงจาก: shorturl.at/nHNQ4 [อ้างถึงวันที่ 17 กุมภาพันธ์ 2565].

พงษ์ธร แซ่อุย. สารเคมียาง. ปทุมธานี : ศูนย์เทคโนโลยีโลหะและวัสดุแห่งชาติ สำนักงานพัฒนาวิทยาศาสตร์และเทคโนโลยีแห่งชาติ กระทรวงวิทยาศาสตร์และเทคโนโลยี, 2548. 4-9. ISBN:974-229-750-9.

การวัลคาไนซ์ยางด้วยลำอิเล็กตรอน [ออนไลน์]. ธันวาคม 2557 เข้าถึงจาก: shorturl.at/cflrP [อ้างถึงวันที่ 3 มีนาคม 2565].

PHETARPORN, V., S. LOYKULNANT, C. KONGKAEW, A. SEUBSAI, and P. PRAPANINAINAR. Composite properties of graphene-based materials/natural rubber vulcanized using electron beam irradiation. New York : ELSEVIER. 2019, 413-424.

CHIRINOS, H., F. YOSHII, and K. MAKUUCHI. Natural rubber latex using gamma rays and electron beam radiation. Kautschuk Gummi Kunststoffe. 2007, 535-541.

KARAAGAC, B., A. AYTAC, and V. DENIZ. Application of radiation technology to rubber and tire industries. Hacettepe Journal of Biology and Chemistry. 2014, 42(1), 24-34.

HAGUE, M.E., N.C. DAFADER, F. AKHTAR, and M.U. AHMED. Radiation dose required for the vulcanization of natural rubber latex. Radiation Physics and Chemistry. 1996, 48(4), 505-510.

MANAILA, E., and others. Radiation vulcanization of natural rubber with polyfunctional monomers. Polymer Bulletin. 2014, 71(1), 57-82.

INTERNATIONAL ORGANIZATION FOR STANDARDIZATION (ISO). ISO 48-4: 2018. Rubber, vulcanized or thermoplastic-Determination of hardness-Part 4: Indentation hardness by durometer method (Shore hardness). Geneva, Switzerland: ISO. 2018.

INTERNATIONAL ORGANIZATION FOR STANDARDIZATION (ISO). ISO 37: 2017. Rubber, vulcanized or thermoplastic-Determination of tensile stress-strain properties. Geneva, Switzerland: ISO. 2017.

INTERNATIONAL ORGANIZATION FOR STANDARDIZATION (ISO). ISO 2285: 2019. Rubber, vulcanized or thermoplastic-Determination of tension set under constant elongation, and of tension set, elongation and creep under constant tensile load. Geneva, Switzerland: ISO. 2019.

จันทรัตน์ วรสรรพวิทย์. การใช้โปรแกรมสำเร็จรูป excel ในการทดสอบแบบเอฟและที. วารสารสำนักบริหารและรับรองห้องปฏิบัติการ. 2552, 5(14), 12-19.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Bulletin of Applied Sciences

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.