The performance test of single-use medical masks: physical characteristics

DOI:

https://doi.org/10.60136/bas.v13.2024.1242Keywords:

Spunbond, Meltblown, Single use mask, ASTM F2100-21, TIS 2424-2565Abstract

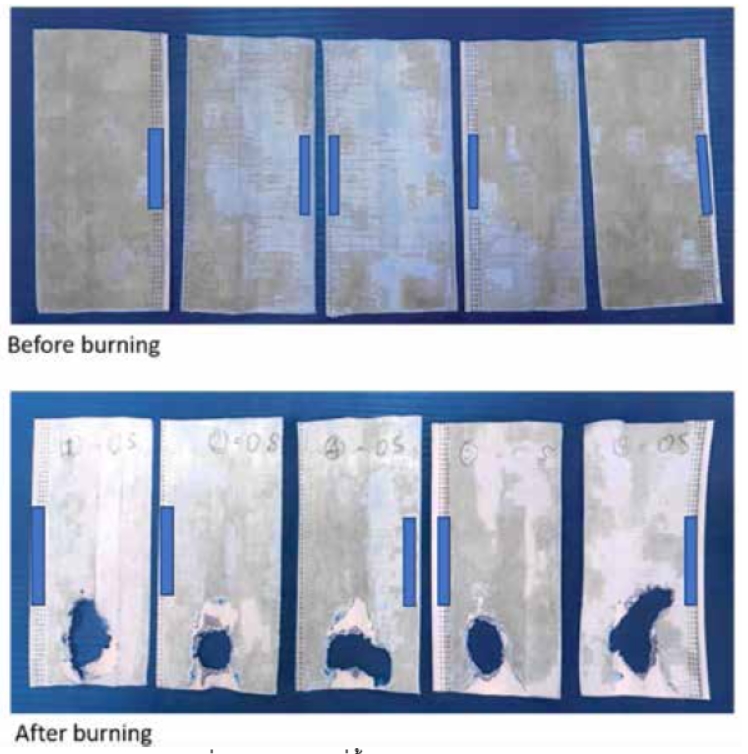

This laboratory report aims to demonstrate methods for testing single-use face masks and report compliance or non-conformity regarding general characteristics, functional properties, and physical characteristics according to the single-use face mask industry product standard requirements (TIS 2424-2565). Physical characteristics testing is based on testing methods according to ASTM F2100-21. The test results showed that the tested mask had a pressure difference of 4 mmH2O/cm2, a resistance to permeability of liquids (synthetic blood) at a minimum pressure of 80 mmHg, face mask flame retardant test was classified in Class 1, and the particle filtration efficiency and bacterial filtration efficiency are 95.7% and 97.6%, respectively. This physical characteristic meets the testing criteria for single-use medical masks, Class 1. They can be tested for biological characteristics to confirm compliance with industrial product standard requirements. As for the study of face mask material properties and structure, results have been reported for manufacturers to analyze and improve to develop product standards further.

References

American Society for Testing and Materials (ASTM). Standard specification for performance of materials used in medical face masks. ASTM F2100-21. West Conshohocken, United States of America: ASTM International; 2021.

American Society for Testing and Materials (ASTM). Standard test methods for vulcanized rubber and thermoplastic elastomers-tension. ASTM D412-16. West Conshohocken, United States of America: ASTM International; 2021.

British Standards Institution (BSI). Medical face masks - Requirements and test methods. BS EN 14683- 2019. London, United Kingdom: BSI; 2019.

American Society for Testing and Materials (ASTM). Standard test methods for resistance of medical face masks to penetration by synthetic blood (Horizontal projection of fixed volume at a known velocity). ASTM F1862/F1862M-17. West Conshohocken, United States of America: ASTM International; 2017.

American Society for Testing and Materials (ASTM). Standard test method for determining the initial efficiency of materials used in medical face masks to penetration by particulates using latex spheres. ASTM F2299/F2299M-03. West Conshohocken, United States of America: ASTM International; 2017.

American Society for Testing and Materials (ASTM). Standard test method for evaluating the bacterial filtration efficiency (BFE) of medical face mask materials, using a biological aerosol of Staphylococcus aureus. ASTM F2101-19. West Conshohocken, United States of America: ASTM International; 2019.

Code of Federal Regulations. Standard for the flammability of clothing textiles. 16CFR Part 1610. United States of America: CFR; 2022.

Tcharkhtchi A, Abbasnezhad N, Zarbini Seydani M, Zirak N, Farzaneh S, Shirinbayan M. An overview of filtration efficiency through the masks: mechanisms of the aerosols penetration. Bioact Mater. 2021;6(1):106- 122. doi: 10.1016/j.bioactmat.2020.08.002.

Xiao Y, Sakib N, Yue Z, Wang Y, Cheng S, You J, et al. Study on the relationship between structure parameters and filtration performance of polypropylene meltblown nonwovens. Autex Res J. 2020;20(4):366- 71. doi: 10.2478/aut-2019-0029.

Midha VK, Dakuri A. Spun bonding technology and fabric properties: a review. J Text Eng Fash Technol 2017;1(4): 126-133. doi: 10.15406/jteft.2017.01.00023.

Essa W, Yasin S, Saeed I, Ali G. Nanofiber-based face masks and respirators as COVID-19 protection: a review. Membranes (Basel). 2021;11(4):250. doi: 10.3390/membranes11040250.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Bulletin of Applied Sciences

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.