Development of Bag-type Semi-precast Concrete for Construction

Keywords:

bagged semi-precast concrete for construction, compressive strength, slump testAbstract

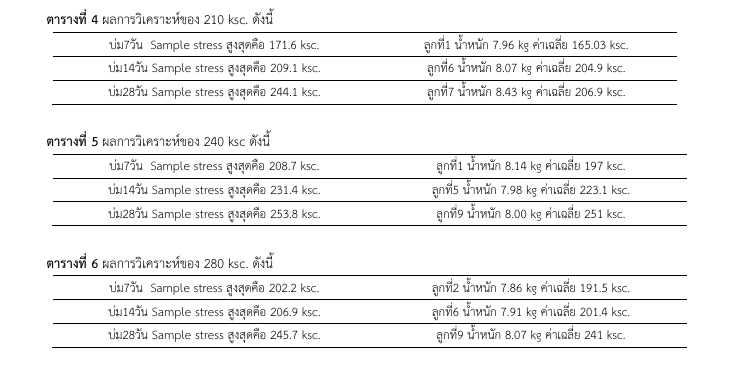

This research studies the development of bagged semi-precast concrete for construction by analyzing the appropriate proportions based on the desired compressive strength. The mixture consists of grade 1 stone, cement and coarse sand without the concrete admixtures. The compressive strength and slump test were conducted on concrete samples in cubic form measuring 15x15x15 cubic centimeter, with curing periods of 7, 14, and 28 days. The results showed that the bagged concrete achieved a maximum compressive strength at 28 days of 206.9, 241, and 251 kilogram / square centimeter. The bagged semi-precast concrete for construction is convenient to user that on a budget and not need to find the proportions of ingredient.

References

Alhozaimy, A. M. (2007). Effect of retempering on the compressive strength of ready-mixed concrete in hot-dry environments, Cement and Concrete Composites, 29, 124-127. https://doi.org/10.1016/j.cemconcomp.2006.08.007.

Aziz, R. F. (2018). Engineering approach to allocate and evaluate performance influencing factors for ready mixed concrete batch plant under different effects, Alexandria Engineering Journal, 57, 3237 – 3247. https://doi.org/10.1016/j.aej.2017.12.004

Dhir, R.K. (1975). Advances in Ready Mixed Concrete Technology, Proceedings of the First International Conference on Ready-Mixed Concrete Held at Dundee University, 1, 1–16. https://doi.org/10.1016/C2013-0-02744-2.

Emiroğlu. M., Yalama. A., and Erdoğdu. Y. (2015). Performance of ready-mixed clay plasters produced with different clay/sand ratios, Applied Clay Science, 115, 221-229. https://doi.org/10.1016/j.clay.2015.08.005

Gebremichael, N. N., Karein, S. M. M, Karakouzian, M., and Jadidi, K. (2019). Investigation of setting time and compressive strength of ready-mixed concrete blended with returned fresh concrete, Construction and Building Materials, 197, 428-435. https://doi.org/10.1016/j.conbuildmat.2018.11.

Ozer-Erdogan, P., Basar, H.M., Erden, I., and Tolum, L. (2016). Beneficial use of marine dredged materials as a fine aggregate in ready-mixed concrete: Turkey example, Construction and Building Materials, 124, 690-704. https://doi.org/10.1016/j.conbuildmat.2016.07.144.

Pacheco, J. N., Brito, J.de., Chastre, C., and Evangelista, L. (2019). Statistical analysis of Portuguese ready-mixed concrete production, Construction and Building Materials, 209, 283 – 294. https://doi.org/10.1016/j.conbuildmat.2019.03.089.

Vieira, L. de B. P., Figueiredo, A. D. de, Moriggi, T., and John, V.M. (2019). Domingues de Figueiredo, Waste generation from the production of ready-mixed concrete, Waste Management, 94, 146-156. https://doi.org/10.1016/j.wasman.2019.05.043.

Xuan, D., Poon, C. S., and Zheng, W. (2018). Management and sustainable utilization of processing wastes from ready-mixed concrete plants in construction: A review, Resources, Conservation and Recycling, 136, 238 – 247. https://doi.org/10.1016/j.resconrec.2018.04.007.

Xuan, D., Zhan, B., and Poon, C.S. (2016). Innovative reuse of concrete slurry waste from ready-mixed concrete plants in construction products, Journal of Hazardous Materials, 312, 65 – 75. https://doi.org/10.1016/j.jhazmat.2016.03.036.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Chandrakasem Rajabhat University

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

บทความที่ได้รับการตีพิมพ์เป็นลิขสิทธิ์ของมหาวิทยาลัยราชภัฏจันทรเกษม

ข้อความที่ปรากฎในบทความแต่ละเรื่องในวารสารวิชาการเล่มนี้เป็นความคิดเห็นส่วนตัวของผู้เขียนแต่ละท่าน ไม่เกี่ยวข้องกับมหาวิทยาลัยราชภัฏจันทรเกษม และคณาจารย์ท่านอื่นในมหาวิทยาลัยแต่อย่างใด ความรับผิดชอบองค์ประกอบทั้งหมดของบทความแต่ละเรื่องเป็นของผู้เขียนแต่ละท่าน หากมีความผิดพลาดใดๆ ผู้เขียนแต่ละท่านจะรับผิดชอบบทความของตัวเองแต่เพียงผู้เดียว

For Author

For Author