WASTE REDUCTION AND PROCESS CAPABILITY EVALUATION IN RUBBER MIXING VIA LEAN SIX SIGMA: A CASE STUDY IN A THAI RUBBER FACTORY

Main Article Content

Abstract

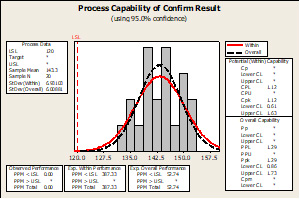

The objective of this research is to enhance the productivity of the rubber-mixing process in the production department, while adhering to feasible constraints and required standards. An analysis of the existing process revealed that productivity was below the standard range, primarily due to inefficient and complex work procedures, excessive pallet consumption for handling both rubber sheets and scraps, overuse of manual labor, high error rates in the semi-automatic weighing process, dependency on numerous forklifts, and excessive waiting times and inventory levels. After implementing improvements by integrating the Lean Six Sigma approach and using the seven quality control tools, a fully automatic weighing system was developed for continuous rubber weighing. The production line was also re-engineered to create a continuous flow between the rubber washing and mixing processes. The results showed that the Process Capability Index (Cpk) was 1.35, indicating a highly capable process. The validation confirmed the elimination of waste in the mixing process. The confidence interval for the process was established as 1.07<Cpk<1.62. The estimated break-even point for the project was 2.28 years.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Articles published in this journal are copyrighted by the Faculty of Industrial Technology. Nakhon Si Thammarat Rajabhat University

In addition, research results and academic works published in the journal It is the independent opinion of the author. The author is responsible for any legal consequences that may arise from the published article. The editorial team and the journal's production team, we don't always have to agree.

References

Leenatham, N. and et al. 2021. “The Efficiency Improvement of STR 20 Block Rubber Production Process by Using Design of Experiments,” Naresuan University Engineering Journal, 16(1): pp. 119–139.

Sudasna-na-Ayudthya, P. and Luangpaiboon, P. 2008. Design and Analysis of Experiments, 1st ed. Bangkok, Thailand: Top Publishing. (in Thai)

Montgomery, D. C. 2019. “Factorial and Fractional Factorial Experiments for Process Design and Improvement,” in Introduction to Statistical Quality Control, 8th ed. New York, USA: John Wiley & Sons, ch. 13, pp. 523–550.

Montgomery, D. C. 2019. “Response Surface Methods and Designs,” in Design and Analysis of Experiments, 10th ed. New York, USA: John Wiley & Sons, ch. 11, pp. 430–436.

Leenatham, A. and Khemavuk, P. 2019. “Process Improvement of PTCA Guide Wire by Using Design of Experiment,” SWU Engineering Journal, 14(2): pp. 12–24. (in Thai)

Semsri, A. 2022. “Determination of Optimum Temperature of Barrel Heater for Reducing Waste in Plastic Injection Molding Process of Tractor Turn Signal Cover Parts using DMAIC Techniques,” Engineering and Technology Horizons, 39(3): pp. 111–130. (in Thai)

Leenatham, N. and Ponpakdee, S. 2024. “The Quality Improvement of Tube Ice Production Process by using Central Composite Design,” Engineering and Technology Horizons, 41(3): pp. 1–19. (in Thai)

Sliva, T. and Ferreira, P. 2017. “Improve the extrusion process in tire production using six sigma methodology,” Procedia Manufacturing, 13: pp. 1104–1111.

Pyzdek, T. and Keller, P. 2019. The Six Sigma Handbook, 5th ed. New York: McGraw Hill.

Ramasamy, S. 2009. Total Quality Management. New Delhi: Tata McGraw Hill.

Breyfogle, F. W. III. 2003. Implementing Six Sigma: Smarter Solutions Using Statistical Methods, 2nd ed. New York: John Wiley & Sons.

Leenatham, N. and et al. 2019. “Reducing of the wasting time in the dirt testing process of rubber by lean six sigma approach: a case study in a rubber factory,” Wichcha Journal, 38(2): pp. 104–119. (in Thai)