The Effect of Acid Treatment Time, Particle Size, and Synthesis Method on the Physical and Mechanical Properties of Dental Materials Produced from Flue Gas Desulfurization (FGD) Gypsum

DOI:

https://doi.org/10.69650/ahstr.2024.1007Keywords:

dental material, dental stone, dental plaster, FGD gypsum, compressive strengthAbstract

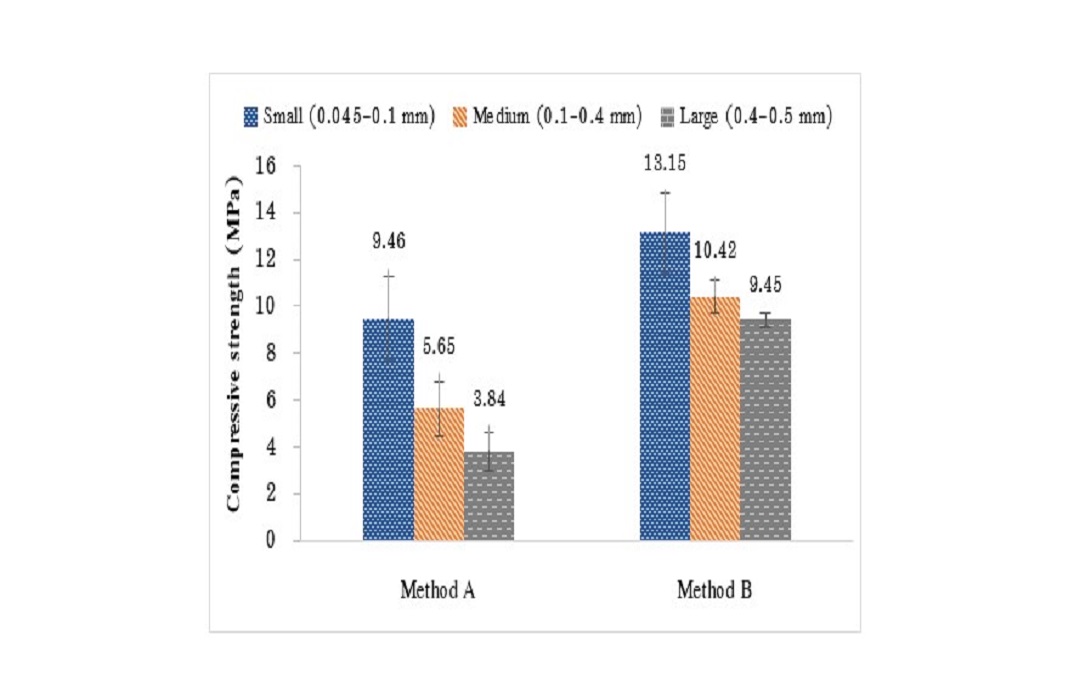

FGD gypsum, a byproduct of coal-fired power plants, is readily available and relatively inexpensive, which makes it an ideal material for a variety of applications. This study considered the use of FGD gypsum as a substitute for natural gypsum in dental materials. The goal of this research was to investigate how acid treatment time, particle size, and the synthesis method impact the physical and mechanical properties of dental materials to be used in a dental study model for training in dental sciences, and for casting a gypsum model after the removal of the impression material from the patient's mouth. The study used various sulfuric acid treatment times (15, 30, and 60 min), particle sizes (less than 0.1 mm, 0.1-0.35 mm, and 0.4-0.45 mm), and synthesis methods (Method A for dental plaster and Method B for dental stone). From the results, an acid treatment time of 15 min was sufficient for removing impurities from the FGD gypsum while enhancing the compressive strength. The smaller particles provided higher compressive strength than the larger particles. FGD gypsum became lighter in color when treated with sulfuric acid, and the crystal structure had a rough and porous surface. The synthesis methods had a significant influence on the physical properties of dental gypsum. The increased alpha calcium sulfate hemihydrate (α-HH) phase content resulted in improved compressive strength. The gypsum synthesized using Method B exhibited the highest compressive strength due to the presence of the α-HH phase of 65.9%. While gypsum synthesized using Method A contained a α-HH phase of 58.9%. For further study, once the suitable conditions for synthesizing gypsum that meet the compressive strength requirements of the ISO standard for dental materials are achieved, there will be ongoing research and development to improve various properties. Additionally, practical applications will be considered, such as using it in conjunction with modern techniques such as 3D printing instead of traditional die-casting methods.

References

Akinnifesi, J., & Ogunbodede, R. (2012). Property optimization in synthetic production of plaster of paris for use as dental material. The Nigerian Journal of Research and Production Volume, 20(1), 1-9.

Azer, S. S., Kerby, R. E., & Knobloch, L. A. (2008). Effect of mixing methods on the physical properties of dental stones. Journal of Dentistry, 36(9), 736-744. https://doi.org/10.1016/j.jdent.2008.05.010

Caillahua, M. C., & Moura, F. J. (2018). Technical feasibility for use of FGD gypsum as an additive setting time retarder for Portland cement. Journal of Materials Research and Technology, 7(2), 190-197. https://doi.org/10.1016/j.jmrt.2017.08.005

EPA. (2008). Agricultural uses for flue gas desulfurization (FGD) gypsum. United States Environmental Protection Agency.

Fu, L., Xia, W., Mellgren, T., Moge, M., & Engqvist, H. (2017). Preparation of high percentage α-calcium sulfate hemihydrate via a hydrothermal method. Journal of Biomaterials and Nanobiotechnology, 08(01), 36-49. https://doi.org/10.4236/jbnb.2017.81003

GII. (2023, May 16). Dental gypsum market - growth, future prospects and competitive analysis, 2023 - 2031. https://www.giiresearch.com/report/act1251902-dental-gypsum-market-growth-future-prospects.html

Guan, Q., Sui, Y., Zhang, F., Yu, W., Bo, Y., Wang, P., Peng, W., & Jin, J. (2021). Preparation of α-calcium sulfate hemihydrate from industrial by-product gypsum: a review. Physicochemical Problems of Mineral Processing, 57(1), 168-181. https://doi.org/10.37190/ppmp/130795

Imelda, D., Octarina, W., & Johan Arief, B. (2020). Setting time of construction gypsum, dental plaster, and white orthodontic gypsum. Journal of Dental Research, Dental Clinics, Dental Prospects, 14(3), 167-170. https://doi.org/10.34172/joddd.2020.036

ISO 6873:2013. (2013). BS EN ISO 6873:2013 Dentistry. Gypsum products [Standard]. BSI Standards Limited.

Koralegedara, N. H., Pinto, P. X., Dionysiou, D. D., & Al-Abed, S. R. (2019). Recent advances in flue gas desulfurization gypsum processes and applications – A review. Journal of Environmental Management, 251, 109572. https://doi.org/https://doi.org/10.1016/j.jenvman.2019.109572

Kostic-Pulek, A., Marinkovic, S., Popov, S., Djuricic, M., & Djinovic-Stojanovic, J. (2005). The treatment of gypsum as a product of the flue gas desulphurization process. Ceramics-Silikaty, 49, 115-119.

Lee, Y., Bigham, J., Dick, W., & Kim, P. (2008). Impact of flue gas desulfurization-calcium sulfite and gypsum on soil microbial activity and wheat growth. Soil Science, 173, 534-543. https://doi.org/10.1097/SS.0b013e318182b049

McCabe, J. F., & Walls, A. W. G. (2008). Applied dental materials (9th ed.) The Blackwell Science.

O'Brien, W. J. (2022, May 10). Dental materials and their selection. Quintessence Publishing. https://library.unmas.ac.id/repository/E-FKG0170.pdf

Panpa, W. (2002). Production of dental stone from flue-gas gypsum. Chulalongkorn University, Bangkok Thailand.

Precision Reports. (2023). Dental Gypsum market - growth, trends and forecast (2023 - 2030). https://www.linkedin.com/pulse/dental-gypsum-market-growth-trends-forecast-2023-8khgf?trk=article-ssr-frontend-pulse_more-articles_related-content-card

Satameth, P., Kukiattrakoon, B., Direksoonthorn, J., Soonhuae, C., Sriburoot, P., & Wetpimon, R. (2014). Surface hardness and setting expansion of plaster cast reinforced with calcium sulfate dihydrate from type IV gypsum product. Songklanakarin Dental Journal, 2(1), 30-38. https://www.dent.psu.ac.th/unit/journal/wp-content/uploads/2022/04/boonlert2014.pdf

Whip Mix Corporation. (2021, February). Whip Mix Gypsum Physical Properties. https://www.whipmix.com/wp-content/uploads/2021/06/Gypsum-Physical-Properties.pdf

Yichao, Z., Ying, W., Jinghai, Z., Jiaxi, L., & Tong, L. (2020). Basic characteristics and comprehensive utilization of FGD gypsum. IOP Conference Series: Earth and Environmental Science, 510(5), 052002. https://doi.org/10.1088/1755-1315/510/5/052002

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Asian Health, Science and Technology Reports

This work is licensed under a Creative Commons Attribution 4.0 International License.